Why Everything Is Made in China: Unpacking the Global Manufacturing Hub

Ever wondered why seemingly everything, from the simplest toys to the most sophisticated electronics, bears the label ‘Made in China’? The phenomenon of China’s dominance in global manufacturing is complex, driven by a confluence of economic, political, and historical factors. Understanding why everything is made in China requires a deep dive into the country’s transformation into the world’s factory. This article will explore the key reasons behind China’s manufacturing prowess, examining its competitive advantages, the evolution of its industrial capabilities, and the potential future of global production.

The Rise of China: A Manufacturing Powerhouse

China’s ascent to becoming the world’s leading manufacturing hub is a story of strategic planning, massive investment, and relentless pursuit of economic growth. The ‘Made in China’ label is now ubiquitous, a testament to the country’s ability to produce goods at a scale and price that few can match.

Labor Costs: A Significant Advantage

One of the most significant factors contributing to China’s manufacturing dominance is its relatively low labor costs. For decades, China offered a vast pool of workers willing to work for wages that were significantly lower than those in developed countries. This labor cost advantage allowed Chinese manufacturers to produce goods at a lower price point, making them highly competitive in the global market. While labor costs have risen in recent years, China still maintains a competitive edge in many industries.

Infrastructure Development: Building a Manufacturing Ecosystem

China’s government has invested heavily in infrastructure development, creating a robust ecosystem that supports manufacturing. This includes extensive transportation networks (high-speed railways, highways, and ports), reliable power grids, and advanced telecommunications infrastructure. These investments have facilitated the efficient movement of goods and materials, reducing transportation costs and lead times for manufacturers. The focus on infrastructure has been a key element of why everything is made in China.

Government Policies and Support: A Helping Hand

The Chinese government has played a crucial role in fostering the growth of its manufacturing sector. Through various policies and support programs, the government has incentivized foreign investment, promoted technological innovation, and provided financial assistance to domestic manufacturers. Special Economic Zones (SEZs) were established to attract foreign investment and encourage export-oriented manufacturing. These zones offered tax breaks, streamlined regulations, and other incentives, making them attractive locations for foreign companies to set up production facilities. The proactive role of the government explains a lot about why everything is made in China.

Supply Chain Efficiency: An Integrated Network

China has developed a highly efficient and integrated supply chain network. This network connects manufacturers with suppliers of raw materials, components, and other inputs, allowing them to source materials quickly and cost-effectively. The concentration of manufacturers in specific regions has also fostered specialization and collaboration, further enhancing supply chain efficiency. This network is a critical component of why everything is made in China.

The Evolution of Chinese Manufacturing

China’s manufacturing sector has undergone a significant transformation over the past few decades. Initially, China focused on producing low-value, labor-intensive goods such as textiles and toys. However, as the country’s economy has grown and its technological capabilities have improved, it has moved up the value chain, producing more sophisticated and higher-value products.

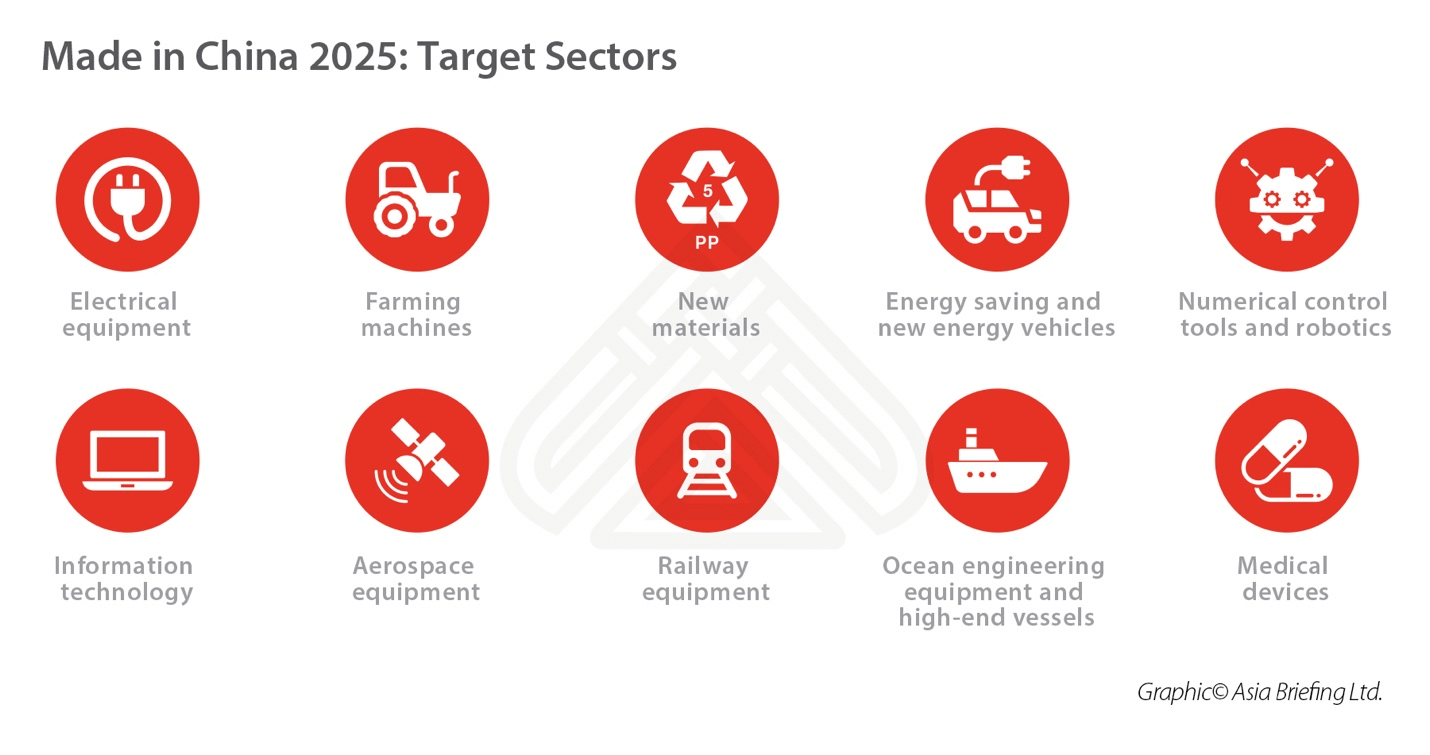

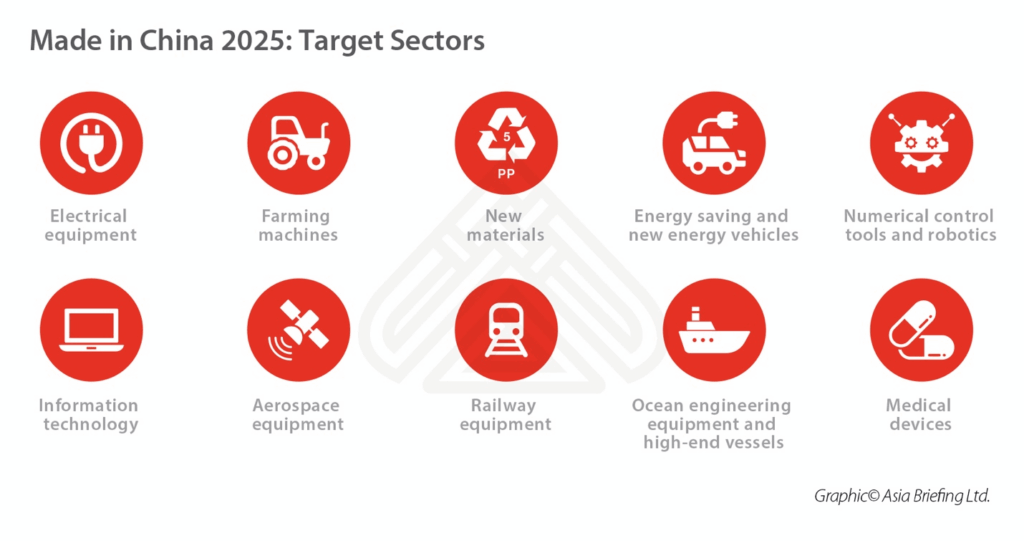

From Low-Cost Production to High-Tech Manufacturing

Today, China is a major player in high-tech manufacturing, producing everything from smartphones and computers to electric vehicles and aerospace components. The country has invested heavily in research and development, and it is home to a growing number of innovative companies. This shift towards high-tech manufacturing is changing the perception of ‘Made in China’ from a symbol of cheap labor to a mark of quality and innovation. This evolution is crucial to understanding why everything is made in China now.

The Role of Foreign Investment and Technology Transfer

Foreign investment has played a crucial role in the development of China’s manufacturing sector. Foreign companies have brought in capital, technology, and management expertise, helping to modernize Chinese factories and improve production processes. Technology transfer has also been a key factor, as foreign companies have shared their know-how with their Chinese partners. This collaboration has accelerated the pace of technological innovation in China. [See also: The Impact of Foreign Investment on China’s Economy]

The Impact of ‘Made in China’

The rise of ‘Made in China’ has had a profound impact on the global economy. It has led to lower prices for consumers, increased global trade, and significant economic growth in China. However, it has also raised concerns about job losses in developed countries, trade imbalances, and environmental issues.

Benefits for Consumers: Lower Prices and Greater Choice

One of the primary benefits of ‘Made in China’ is lower prices for consumers. Chinese manufacturers can produce goods at a lower cost than manufacturers in developed countries, allowing them to offer products at more competitive prices. This has made goods more affordable for consumers around the world, particularly in developing countries. Consumers also benefit from a wider range of choices, as Chinese manufacturers produce a vast array of products to meet diverse needs and preferences.

Challenges for Developed Countries: Job Losses and Trade Imbalances

The rise of ‘Made in China’ has also presented challenges for developed countries. As manufacturers have moved production to China, many jobs have been lost in developed countries. This has led to concerns about unemployment and economic inequality. The large trade surplus that China has with many developed countries has also raised concerns about trade imbalances. [See also: The Future of Manufacturing in the United States]

Environmental Concerns: Sustainability and Responsibility

The rapid growth of China’s manufacturing sector has also raised environmental concerns. The country’s heavy reliance on coal-fired power plants has contributed to air pollution and greenhouse gas emissions. There are also concerns about the environmental impact of manufacturing processes, such as the discharge of pollutants into rivers and lakes. However, China is taking steps to address these environmental challenges, investing in renewable energy and implementing stricter environmental regulations. Addressing these concerns is vital for sustainable manufacturing and further explains why everything is made in China with ethical responsibility. [See also: China’s Environmental Policies and Their Impact]

The Future of Manufacturing in China

The future of manufacturing in China is uncertain, as the country faces a number of challenges, including rising labor costs, increasing competition from other low-cost countries, and growing environmental concerns. However, China also has a number of strengths, including a large and skilled workforce, a well-developed infrastructure, and a strong government commitment to innovation.

Rising Labor Costs and Automation

Rising labor costs are putting pressure on Chinese manufacturers to automate their production processes. Automation can help to reduce labor costs, improve productivity, and enhance product quality. China is investing heavily in robotics and automation technologies, and it is becoming a leader in this field. This shift towards automation will likely change the nature of manufacturing jobs in China, requiring workers to have more technical skills. The investment in automation is changing why everything is made in China, focusing on efficiency.

Competition from Other Low-Cost Countries

China is facing increasing competition from other low-cost countries, such as Vietnam, India, and Bangladesh. These countries offer even lower labor costs than China, making them attractive locations for manufacturers looking to reduce costs. However, these countries often lack the infrastructure and supply chain efficiency that China has developed. [See also: The Rise of Southeast Asia as a Manufacturing Hub]

The ‘China Plus One’ Strategy

Many companies are adopting a ‘China Plus One’ strategy, which involves diversifying their supply chains by establishing production facilities in other countries in addition to China. This strategy helps to reduce risk and mitigate the impact of disruptions to the Chinese supply chain. The ‘China Plus One’ strategy is evolving the understanding of why everything is made in China by considering diversification.

Conclusion: The Enduring Legacy of ‘Made in China’

Why everything is made in China is a question with a complex answer, rooted in decades of strategic planning, massive investment, and relentless pursuit of economic growth. While challenges lie ahead, China’s manufacturing sector is likely to remain a major force in the global economy for years to come. The ‘Made in China’ label will continue to be a familiar sight on products around the world, a testament to the country’s enduring manufacturing prowess. The future may bring changes, but the legacy of China’s manufacturing dominance is undeniable.