Why Is Almost Everything Made in China? Unraveling the Global Manufacturing Powerhouse

Ever wondered why seemingly every product, from the simplest household item to the most sophisticated electronics, bears the label “Made in China”? It’s a question that reflects the dramatic shift in global manufacturing over the past few decades. Understanding why almost everything is made in China requires a deep dive into economics, history, and geopolitical strategy. This article explores the complex factors that have cemented China’s position as the world’s manufacturing hub.

The Rise of China as a Manufacturing Giant

China’s dominance in manufacturing didn’t happen overnight. It’s the result of a carefully orchestrated plan, beginning with economic reforms initiated by Deng Xiaoping in the late 1970s. These reforms, known as the “opening up” policy, shifted China from a centrally planned economy to a market-oriented one, attracting foreign investment and fostering rapid industrial growth.

Cheap Labor: The Initial Advantage

Initially, China’s primary advantage was its vast and inexpensive labor force. Western companies, eager to reduce production costs, flocked to China to take advantage of significantly lower wages. This influx of foreign investment fueled the growth of factories and industries, transforming China into a global manufacturing powerhouse. While labor costs have increased in recent years, they still remain competitive compared to many developed countries.

Government Support and Infrastructure Development

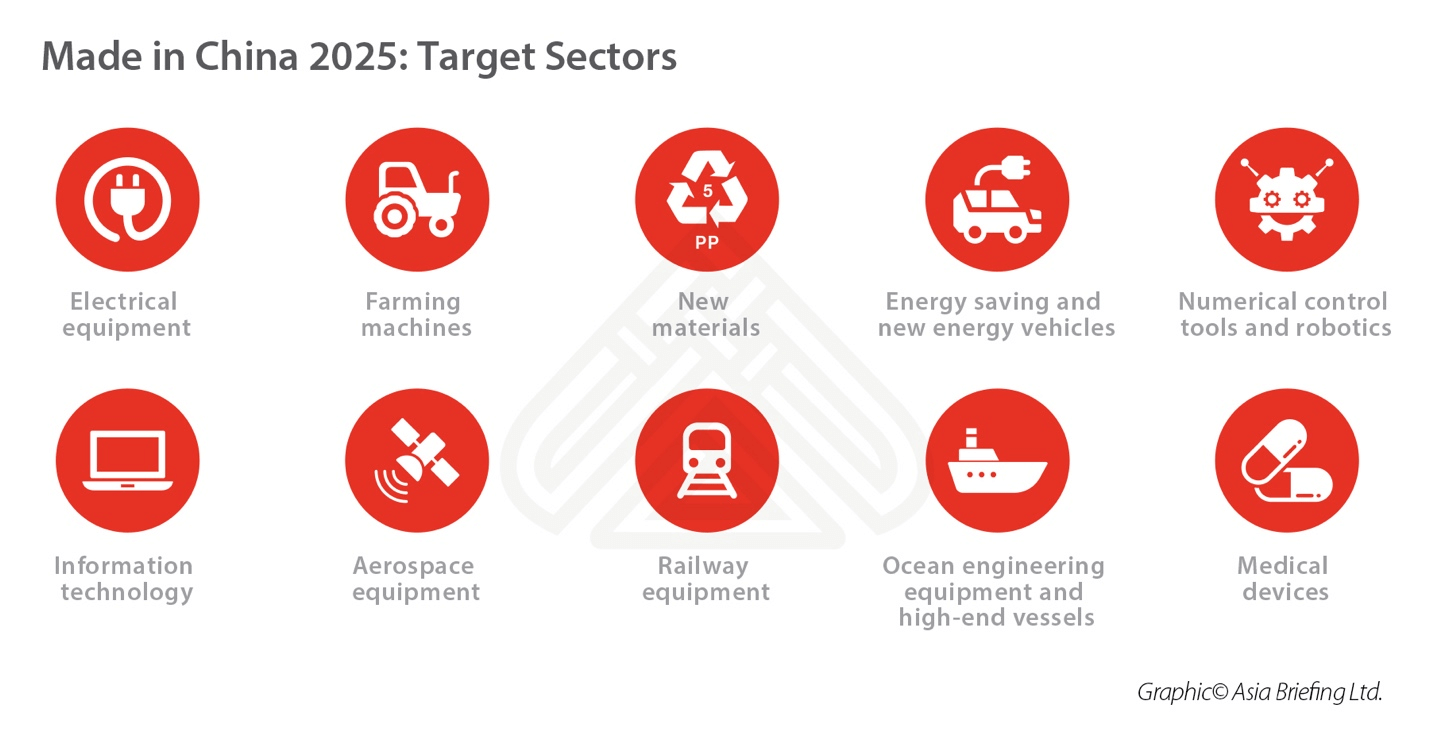

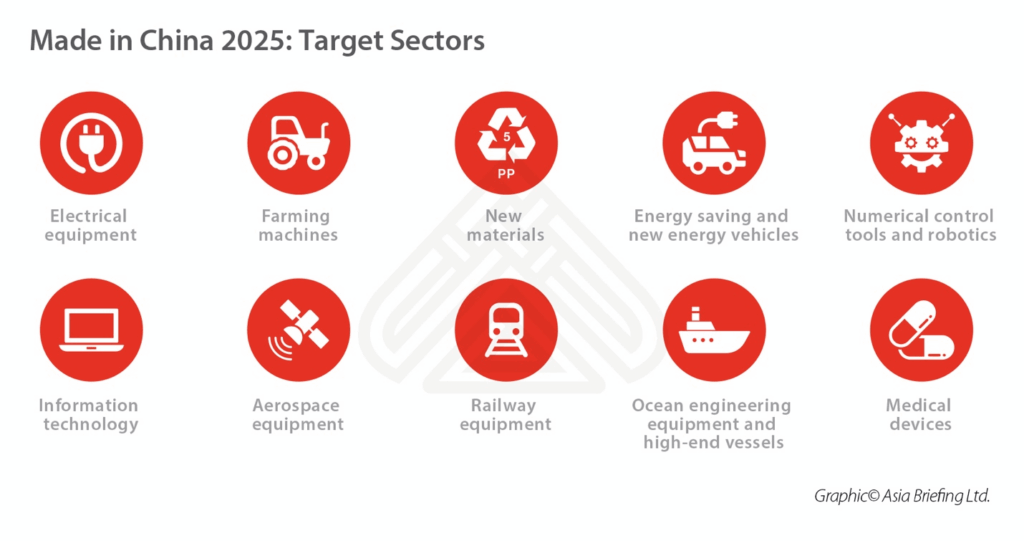

The Chinese government played a crucial role in facilitating this transformation. It invested heavily in infrastructure development, building modern ports, highways, and railways that streamlined the movement of goods and materials. Special Economic Zones (SEZs) were established, offering tax incentives and reduced regulations to attract foreign businesses. This proactive approach created a favorable environment for manufacturing to flourish. The government also actively promoted technology transfer and industrial upgrading, enabling Chinese companies to move up the value chain.

A Complete Manufacturing Ecosystem

Over time, China has developed a comprehensive manufacturing ecosystem. This means that almost all the components and raw materials needed to produce a wide range of goods are readily available within the country. This reduces lead times, lowers transportation costs, and gives Chinese manufacturers a significant advantage over competitors in other countries. The concentration of suppliers and manufacturers in specific regions, like the Pearl River Delta and the Yangtze River Delta, creates economies of scale and fosters innovation. It’s one reason why almost everything is made in China.

The Impact on Global Trade and Economies

China’s dominance in manufacturing has had a profound impact on global trade and economies. While it has provided consumers worldwide with access to affordable goods, it has also led to job losses in manufacturing sectors in developed countries. The trade imbalance between China and many other nations has become a significant point of contention, leading to trade disputes and calls for protectionist measures.

The Pros and Cons for Consumers

For consumers, the availability of inexpensive goods from China has been a boon. It has allowed people to purchase more products for less money, raising living standards and fueling consumer spending. However, concerns about product quality, safety, and environmental standards have also arisen. The perception that “almost everything is made in China” often comes with an assumption about lower quality, although this is not always the case.

The Challenges for Developed Nations

Developed nations have faced challenges in competing with China’s low-cost manufacturing. Many companies have moved their production facilities to China to remain competitive, leading to job losses and a decline in manufacturing output in their home countries. This has prompted governments to explore strategies to revitalize their manufacturing sectors, such as investing in advanced technologies, promoting innovation, and providing incentives for companies to reshore their production.

Is the “Made in China” Era Coming to an End?

While China remains the world’s dominant manufacturing hub, there are signs that the “Made in China” era may be evolving. Rising labor costs, increasing environmental regulations, and geopolitical tensions are prompting companies to diversify their supply chains and explore alternative manufacturing locations. Countries like Vietnam, India, and Mexico are emerging as potential alternatives, offering lower labor costs and favorable investment climates. However, none of these countries currently possess the same scale and infrastructure as China. The question of whether almost everything is made in China will remain true in the future is still open.

The Rise of Automation and Reshoring

Advances in automation and robotics are also playing a role in reshaping the global manufacturing landscape. As automation becomes more affordable and accessible, companies in developed countries are increasingly able to bring manufacturing back home, reducing their reliance on low-cost labor in China. This trend, known as reshoring or onshoring, could lead to a more balanced distribution of manufacturing activity around the world.

Geopolitical Considerations

Geopolitical tensions, particularly the trade war between the United States and China, are also influencing companies’ supply chain decisions. Many companies are seeking to reduce their exposure to geopolitical risks by diversifying their sourcing and manufacturing locations. This trend is likely to accelerate in the coming years, further eroding China’s dominance in global manufacturing. The phrase “almost everything is made in China” might soon become less accurate.

The Future of Global Manufacturing

The future of global manufacturing is likely to be more diversified and decentralized. While China will likely remain a major manufacturing hub for the foreseeable future, other countries will continue to emerge as viable alternatives. Technological advancements, geopolitical considerations, and changing consumer preferences will all play a role in shaping the global manufacturing landscape. The focus will shift towards more sustainable and resilient supply chains, with companies prioritizing factors such as ethical sourcing, environmental responsibility, and supply chain security. The reality of why almost everything is made in China is becoming more complex.

The Importance of Innovation and Sustainability

In the long run, innovation and sustainability will be key to maintaining a competitive edge in global manufacturing. Companies that invest in research and development, adopt sustainable manufacturing practices, and prioritize ethical sourcing will be best positioned to thrive in the evolving global landscape. Consumers are increasingly demanding products that are not only affordable but also environmentally friendly and ethically produced. This trend will further incentivize companies to adopt more sustainable and responsible manufacturing practices. The era of “almost everything is made in China” might transition into an era of “responsibly made globally”.

The Role of Government Policies

Government policies will also play a crucial role in shaping the future of global manufacturing. Governments can support their domestic manufacturing sectors by investing in infrastructure, promoting innovation, providing incentives for reshoring, and implementing trade policies that create a level playing field. They can also encourage companies to adopt sustainable manufacturing practices by providing tax incentives and subsidies for green technologies. Ultimately, a combination of government policies, technological advancements, and changing consumer preferences will determine the future of global manufacturing and whether or not the statement that almost everything is made in China remains true.

In conclusion, the prevalence of products “Made in China” is a complex phenomenon rooted in economic reforms, low labor costs, government support, and the development of a comprehensive manufacturing ecosystem. While China’s dominance in manufacturing has brought benefits to consumers worldwide, it has also created challenges for developed nations and raised concerns about product quality and environmental standards. As the global manufacturing landscape continues to evolve, companies will need to adapt to changing conditions by diversifying their supply chains, investing in automation, and prioritizing innovation and sustainability. The future will likely see a more balanced and diversified global manufacturing system, where the phrase “almost everything is made in China” becomes less of a reflection of reality.

[See also: The Future of Global Supply Chains]

[See also: Impact of US-China Trade War]

[See also: Reshoring Initiatives in Developed Countries]